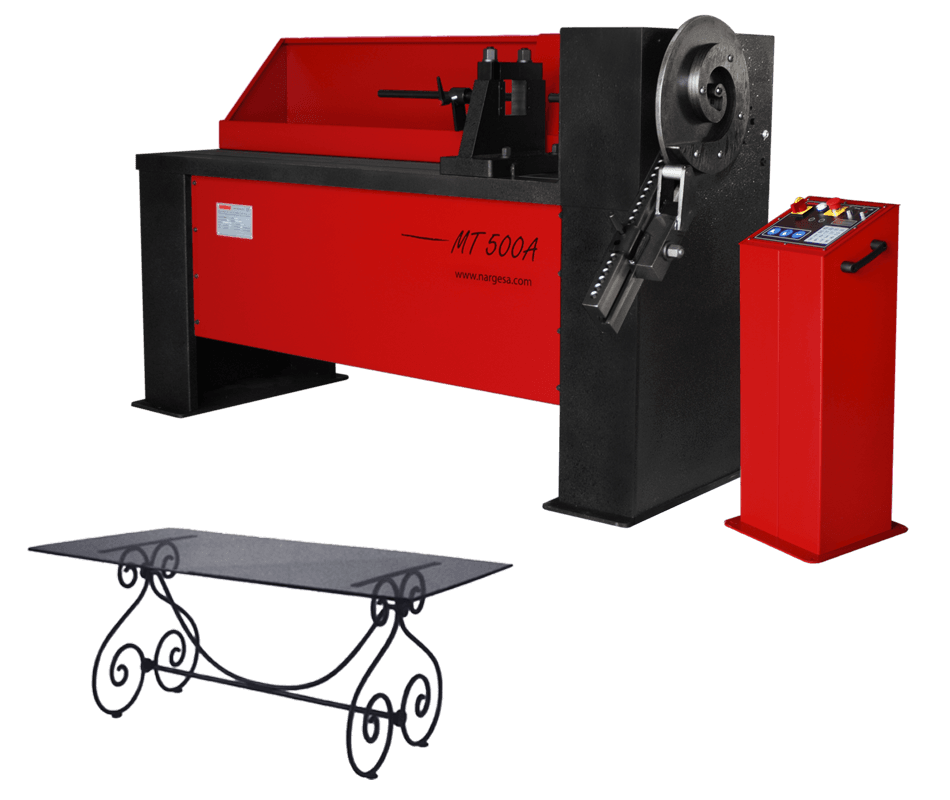

Automatic Wrough Iron machine MT 500A NARGESA.

It was patented by Prada Nargesa several years ago and this makes us be a leading company in manufacturing this kind of equipment. It has b een manufactured in a welded and mechanized steel monoblock. It has been thought to work iron in cold. It’s ideal forb making all kinds of parts for the ornamental forging, balausters, scrolls, etc… Used in window grills, handrails, tables, chairs, doors, fences, windows etc…. Making a lot of different shapes in round, square and tubular profiles, flat bar, handrails, etc…

Technical features

Working method by twisting and flexion in COLD.

Machine suitable for small, medium and big productions.

Safe and reliable transmision by a motor reducer with treated flat pinions, acomplishing a great performance with little maintenance.

Its perfect for making all kind of standard ornamental pieces and essencial to make your own designs which are much more demanded in the market. The pieces as requested by architects, technicians and final users make it an indispensable tooling in a blacksmith workshop.

It’s got two working sites, one for twisting and another one for bending with no neck limit. It means big sized pieced can be made, unlike in other machines of this kind in the market..

In order to make this kind of special jobs, Nargesa provides you under request either the tooling or the fitting discs so the very customer can create his own designs.

The forging equipment Nargesa MT500A is equipped with a set of tooling by means of which a great number of pieces can be made: Twisting, scrolls, hooks, chains… (More information at STANDARD TOOLING at the bottom of the page).

There is also the possibility of purchasing optional tooling: Belly Top Railing, British Rail, Flat bent rings, ornamental baskets… (More information at OPTIONAL TOOLING at the bottom of the page).

Technical Characteristiques

Maximum twisting Capacity 40 mm or 1 3/8″ inches.

Maximum bending capacity: 25 mm or 1″ inches.

Maximum scrolling and bending capacity in flat bar, clod or hadrail 50×10 mm or 2″x 3/8″ inches.

Possibility of buying the tooling for the machine in mm or inches.

Max. continuous twisting length: 1.620 mm.

MOtor power: 4Kw / 5,5 HP.

CNC programmer to make high productions.

3-phased tension: 230/400 V.

Adjustable rotation speed from 0 to 10 r.p.m.

Palletized lower bench to move the machine easily to the working site or storage.

The machine is delivered completely assembled.

Packing with fumigated wooden pallet NIMF 15 and 3-layered cardboard box suitable for sea freight.

Optional: COmplete wooden packing with NIMF15.

Its robustness, versatility, cotrol programmer, productivity and easy handling, make it one of the best machines for a blacksmith workshop.

Automatic Decorative Wrough Iron MT150A NARGESA.

Was patented by Prada Nargesa many years ago and it makes us become a leading company at manufacturing this kind of equipment. It has been made in a welded and mechanized steel monoblock. It is thought to work cold iron. Ideal for making all kind of pieces for the ornamental forging, balausters, volutes, etc… Used in: Window grills, balausters, tables, chairs… making a lot of different shapes in round, square, tubular profiles, hanrails, flat bars, etc…

Technical features

Working method by twisting and flexion in COLD.

Machine suitable for small, medium and big production.

Safe and reliable transmision by a mmotor reducer with flat treated pinions, achieving a remarkable performance ans least maintenance.

Perfect formaking all kinds of ornamental standard parts and essential to make our own designs, a lot more demanded in the market. The pieces requested by architects, technicians and final customers, make it a very important tooling in a blacksmith workshop.

In order to make this kind of special job, Nargesa provides the user with the fitting plates, under request, so the very customer can make his own designs himself.

The twisting machine Nargesa MT150A is equipped with a complete set of standard tooling, by means of which tha user can make a great deal of shapes: twisted, scrolls, bendings, hooks, chains,… (More information in STANDARD TOOLING at the bottom of this page).

There is also the possibility of buying optional tooling: Belly top railing tooling, British rail, flat ben rings, decorative baskets… (More information in OPTIONAL TOOLING at the bottom of this page).

Technical features

Max. twisting capacity 20 mm or 3/4″ inch.

Max. bending capacity 16 mm or 5/8″ inch.

Max twisting and bending capacity in flat bar, clod or hadrail 35X10 mm or 1 1/4″X3/8″ inch.

Possibility of buying the tooling for the machine in mm or inches.

Max. continuous scrolling length 960 mm.

Engine power: 0,37Kw / 0,5 HP.

CNC programmer to repeat series, piece counter, automatic unbolt, memories…

Adjustable millimeter scale on its head to make all parts the same.

Electric panel command with double button, right and left , which makes it a very easy handling machine.

2-phased tension: 230 V. Single phased.

For single phased machines please ask quotation.

Rotation speed controller

Adjustable rotation speed from 0 to 9 r.p.m.

Lower bench palletized to move the machine easily to the working site or storage.

The machine is delivered completely mounted.

Packaging with fumigated wooden pallet NIMF 15 and a 3-layered cardboard box suitable for sea freight.

Optional complete wooden packing NIMF15. Its robustness, versatility and easy handling condition turn it into one of the best machines for an ornamental blacksmith workshop.

All our products are manufactured in our facilities in Spain. Electric and hydraulic components are completely standard and from the best European leading trademarks with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc…