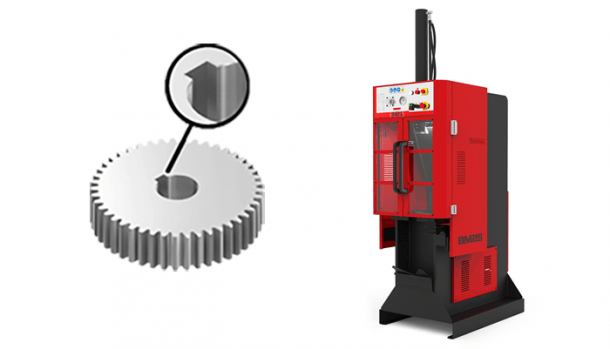

Hydraulic Broaching machine BM25 NARGESA has been fabricated in a welded and mechanized steel monoblock. It’s a machine useful for making notches and keyways in all kinds of pieces: sprockets, pulleys, gears…

It is also used like a press to unbolt oxidated parts, assembling and dismantling bearings…

Technical features

The Vertical Broaching machine BM25, has been thought for small medium productions, it is characterized by its great versatility, reliability, easy use, fast setting up and effectiveness:

- Versatility: It’s used for making small and big pieces. All kinds of broaching and different tolerances. 2 mm keyways from 2 up to 25mm or 1” inch. It is also used like a press to unbolt oxidated parts, assembling and dismantling bearings…

- Reliability: Because of its use, the keyway is always made with the required tolerance and parallelism.

- Easy use: Anyone can make a keyway, ther’s no need to be a skillful operative.

- Fast setting up: The preparation time of the machine before making a broaching operation is approximately 1 min.

- Effectiveness: The machine can be moved easily next to a lathe or machining center. While those machines work, the same operative can make the broaching operation.

Structure

- Mechanized single-block bench

- Lower bench palletized to move the machine easily to the working site or storage.

- LED front lightning.

- Manual operation for a better broaching control.

- Low noise level which improves the working quality of the operator.

- Front polycarbonate protection that allows to see the broaching process.

- Front opening with safety hinges.

- Tooling supplied as standard for the positioning of the parts. This tool is adjusted and fixed to the work bench in the exact position so that the broaching piece is placed easily and quickly in its correct position. There is no need to hold the piece.

- Hydraulic oil CEPSA HYDRAULIC HM 68

Broaches

- The broaces we offer are one of the best trademarks in the market, internationally speaking.

- They are manufactured under strict quality controls, guaranteing the higher liability and durability.

- Made in the USA.

- Some shims are provided with each broach, the ones used for accomplising the required tolerance.

- Broaches in millimeters and inches.

- Broaches of different kinds and tolerances: ISO J-9, ISO P-9.

Control panel

- The control panel is very intuitive and easy to use.

- It includes the conversion chart from pressure to tons.

- Broaching pressure regulator with pressure manometer.

Safety

- The Broaching machine BM25 incorporates all safety devices according to CE regulations.

DETAILED FEATURES

- Neck: The 300mm neck allows to broach pieces up to 600mm in diameter, without any problem.

- Front polycarbonate guards: The two front doors incorporate polycarbonate windows so that the operator can control the broaching process at all times, in total safety.

- Lighting on the broaching table: It is very important to count on a proper lighting inside the broaching cabin, so the operator can control the whole broaching process.

- Drawer for chips collection: The machine has a drawer where all the chip that is generated during the broaching process is collected. This is a removable drawer which can be easily emptied.

- Pressure regulator: By using the pressure regulator and the pressure manometer installed in the machine, we can adjust the working pressure so that it is the ideal one for each broaching operation.

The broaces we offer are one of the best trademarks in the market, internationally speaking. They are manufactured under strict quality controls, guaranteing the higher liability and durability, Made in the USA. Some shims are provided with each broach, the ones used for accomplising the required tolerance.

- Broaches in millimeters and inches.

- Broaches of different kinds and tolerances: ISO J-9, ISO P-9.

CHARACTERISTICS OF THE MACHINE

- Motor power: 2,2 Kw / 3 Hp.

- 3-phased tension: 230/400 V.

- Hydraulic power: 10 Tn.

- Max. broaching capacity: 25 mm.

- Working speed: 24 mm/s.

- Return speed: 54 mm/s.

- Pump Flow: 7,5 liters.

- Capacity of Hydraulic Tank: 25 liters

- Shank displacement: 600 mm.

- Goosneck: 300 mm.

- Max. piece diameter: 600 mm (For different sizes, please ask the manufacturer)

- Bench dimensions: 420 mm x 420 mm.

Packing with steel pallet and retractile film

Optional: Complete wooden packing NIMF15

Its versatility, reliability, productivity and easy handling make it one of the best machines for a maintenance worskshop or medium production factory. By medium production we mean less than 350 units.

All our products are manufactured in our facilities in Spain. Hydraulic and electronic components are completely standard from the best European leading trademarks, with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato…